Introduction

In this article, we will explore the production process of metal architectural decorative mesh and delve into the key focus areas of quality control. We will examine why quality control is paramount, the steps involved in the process, and the challenges manufacturers face. So, let's dive in!

Understanding Metal Architectural Decorative Mesh

Definition and Purpose

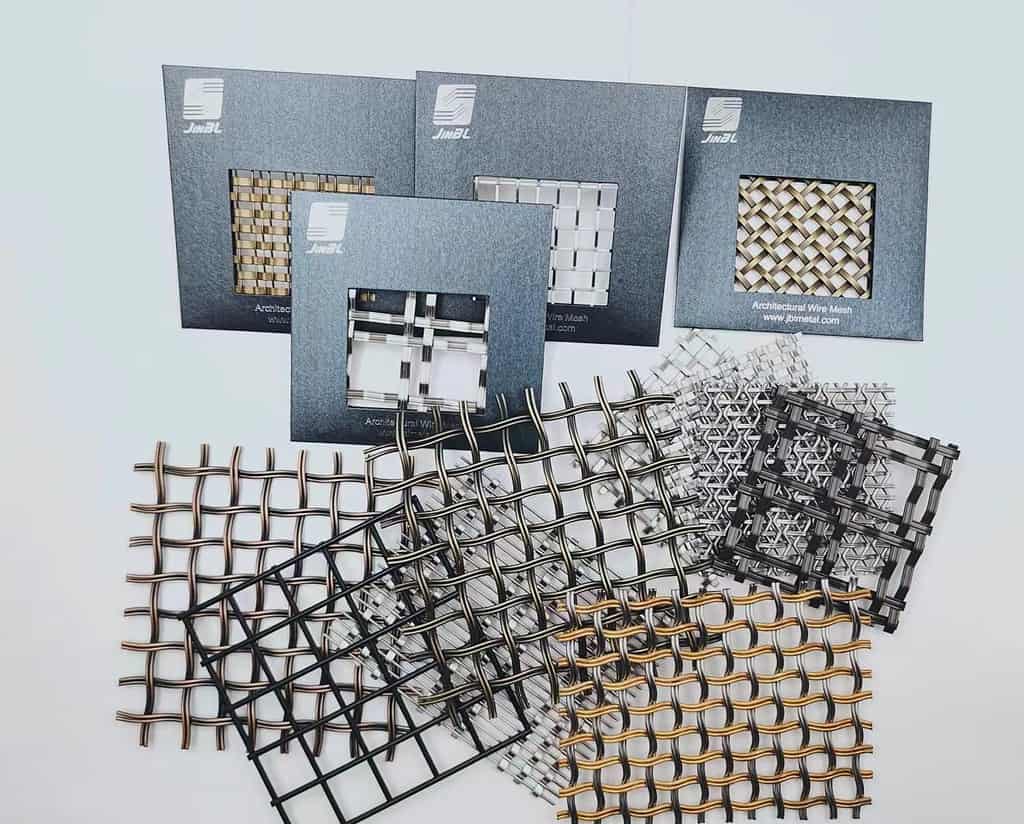

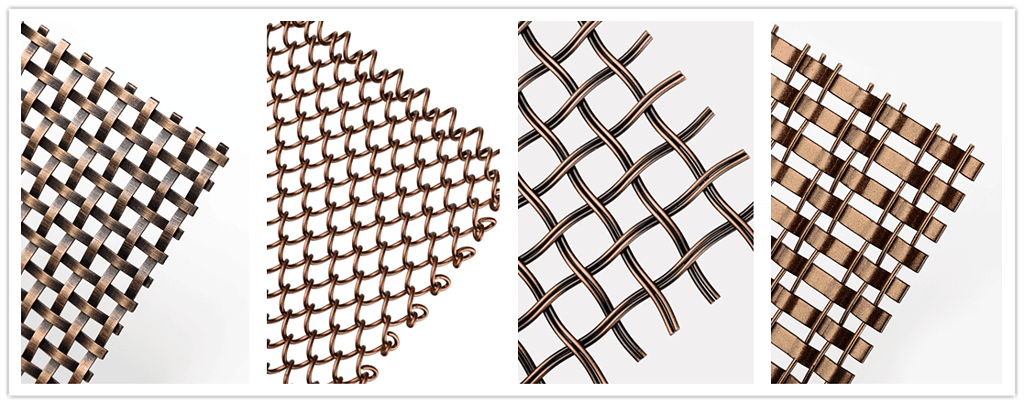

Metal architectural decorative mesh, also known as architectural wire mesh or metal mesh cladding, refers to a range of woven or welded wire products that possess both functional and decorative qualities. It typically consists of interwoven or interconnected wires, forming intricate patterns and designs.

The primary purpose of metal architectural decorative mesh is to enhance the visual appeal of a structure while providing practical functionalities. It serves as a versatile material for interior and exterior applications, offering benefits such as light diffusion, ventilation, sun shading, privacy, and security.

Common Applications

Metal architectural decorative mesh finds applications in a wide array of architectural projects. Some common uses include:

1.Building facades: Mesh panels can be used to create striking facades that provide ventilation, daylighting, and privacy, while also acting as a sunshade.

2.Interior design: Mesh partitions, room dividers, and suspended ceilings add an artistic touch to interior spaces, allowing for light transmission and unique spatial separation.

3.Safety and security: The strength and durability of the mesh make it suitable for safety barriers, security screens, and fences.

4.Signage and branding: Mesh can be utilized to create eye-catching signage and branding elements, both indoors and outdoors.

Production Process of Metal Architectural Decorative Mesh

To achieve the desired characteristics and visual appeal, the production process of metal architectural decorative mesh involves several stages. Let's explore these steps in detail.

Selection of Materials

The quality of the final product heavily relies on the choice of materials. High-grade metals, such as stainless steel, aluminum, or bronze, are often preferred due to their corrosion resistance, strength, and aesthetic properties. The selection of the appropriate metal alloy ensures the mesh can withstand environmental factors and maintain its appearance over time.

Design and Engineering

Before fabrication begins, the design and engineering phase plays a crucial role in translating architectural concepts into tangible mesh patterns. Designers work closely with architects and engineers to understand project requirements, create detailed drawings, and determine the appropriate wire diameter, mesh aperture, and overall dimensions. This phase ensures that the final product aligns with the desired aesthetic and functional objectives.

Fabrication Techniques

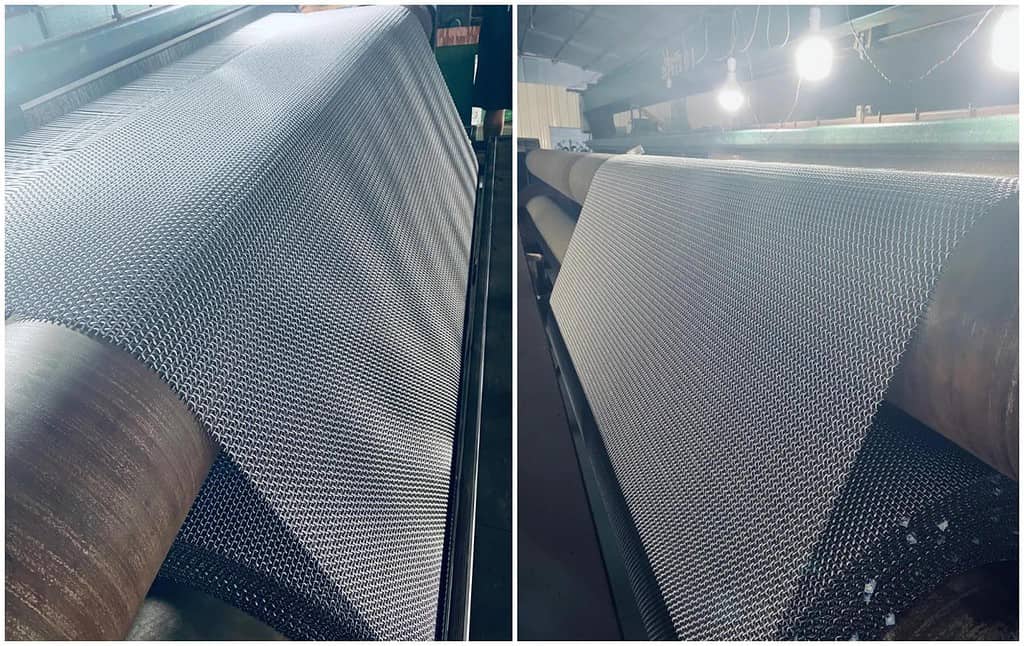

Once the design is finalized, fabrication techniques are employed to bring the mesh to life. Woven mesh is created by interlacing wires horizontally and vertically using specialized looms. On the other hand, welded mesh is formed by spot-welding intersecting wires at their contact points. Skilled technicians operate the machinery and carefully monitor the process to ensure accuracy and precision.

Surface Treatment

To enhance the appearance and protect the mesh from corrosion or environmental damage, surface treatments are applied. Common surface treatments include powder coating, anodizing, or painting, which provide an additional layer of protection while allowing for customization in terms of color and finish.

Importance of Quality Control in the Production Process

Quality control is of paramount importance in the production of metal architectural decorative mesh. It ensures that the final product meets the specified design requirements, performs its intended functions, and withstands the test of time. Let's explore the key reasons why quality control is vital.

Ensuring Structural Integrity

One of the primary focuses of quality control is to verify the structural integrity of the mesh. Rigorous testing and inspection procedures are employed to ensure that the mesh can withstand the expected loads, pressures, and environmental conditions it will encounter. This includes testing for tensile strength, impact resistance, and load-bearing capacity.

Meeting Design Specifications

Metal architectural decorative mesh is often an integral part of an architectural vision. Quality control measures are implemented to ensure that the final product aligns with the design specifications, including wire diameter, mesh aperture, pattern accuracy, and overall dimensions. This attention to detail guarantees that the mesh contributes harmoniously to the overall aesthetics of the structure.

Enhancing Aesthetic Appeal

The visual impact of metal architectural decorative mesh is crucial to its application. Through quality control processes, manufacturers can meticulously inspect the mesh for any visual defects, such as inconsistencies in the pattern, surface imperfections, or color variations. By maintaining a high level of aesthetic quality, the mesh becomes a captivating feature of the architectural design.

Ensuring Durability and Longevity

Architectural projects demand materials that can withstand the test of time. Quality control procedures are essential to assess the durability and longevity of the mesh. This includes evaluating the corrosion resistance of the materials used, conducting weathering tests, and verifying the effectiveness of surface treatments. By ensuring the longevity of the mesh, manufacturers provide a reliable and long-lasting solution to their clients.

Key Steps in Quality Control for Metal Architectural Decorative Mesh

The quality control process for metal architectural decorative mesh involves several critical steps that manufacturers undertake to ensure the highest standards are met. Let's explore these steps in detail.

Material Inspection

The quality control process begins with a thorough inspection of the incoming raw materials. This includes verifying the material composition, checking for any surface defects or impurities, and ensuring compliance with industry standards and specifications. By selecting the right materials from the start, manufacturers lay the foundation for a high-quality end product.

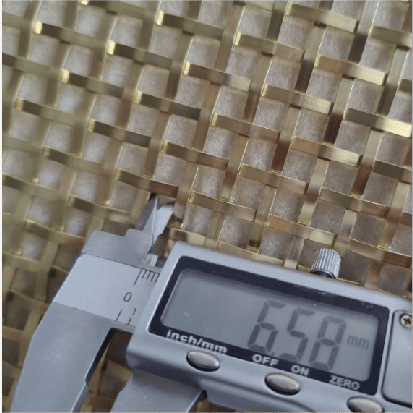

Dimensional Accuracy and Tolerance Checks

Accurate dimensions are crucial for proper installation and functionality of metal architectural decorative mesh. Quality control personnel employ precise measuring techniques and specialized tools to verify the dimensional accuracy of the mesh, including wire diameter, mesh aperture, and panel dimensions. Tolerance checks ensure that the mesh meets the specified requirements and tolerances set by the design.

Strength and Load Testing

To guarantee the structural integrity of the mesh, strength and load testing are performed. Samples of the mesh are subjected to various mechanical tests, such as tension and compression tests, to evaluate their load-bearing capabilities. These tests ensure that the mesh can withstand the intended loads and pressures without deformation or failure.

Surface Finish Assessment

The visual appearance and surface quality of metal architectural decorative mesh significantly impact its overall appeal. Quality control processes include a comprehensive assessment of the surface finish, ensuring it is free from defects, scratches, or blemishes. Techniques such as visual inspection, gloss measurement, and color consistency checks are employed to maintain the desired aesthetic standards.

Packaging and Shipping Checks

To prevent damage during transportation and handling, quality control measures extend to the packaging and shipping stage. Proper packaging materials, protection, and labeling are used to ensure the mesh reaches its destination in pristine condition. This includes verifying that the packaging meets international shipping standards and the mesh is securely packed to prevent any damage during transit.

Quality Control Instruments and Techniques

To facilitate effective quality control in the production of metal architectural decorative mesh, manufacturers utilize various instruments and techniques. Let's explore some commonly employed ones.

Non-Destructive Testing Methods

Non-destructive testing (NDT) methods are used to assess the quality of the mesh without causing damage or altering its properties. Techniques such as visual inspection, ultrasonic testing, magnetic particle inspection, and dye penetrant inspection can detect surface defects, material inconsistencies, or internal structural flaws. NDT helps identify any issues that might compromise the quality of the final product.

Quality Assurance Certifications

Many manufacturers seek quality assurance certifications to validate their commitment to quality control. Certifications like ISO 9001 ensure that the production processes adhere to international quality standards. By obtaining such certifications, manufacturers demonstrate their dedication to delivering high-quality metal architectural decorative mesh to their customers.

Quality Control Challenges and Solutions

While quality control is crucial, manufacturers face several challenges throughout the production process. Let's explore some common challenges and the corresponding solutions.

Addressing Variations in Material Properties

Metal alloys used in the production of mesh can sometimes exhibit variations in their properties. To address this challenge, manufacturers implement strict material inspection procedures to identify and segregate any non-conforming materials. By maintaining a consistent and reliable source of materials, manufacturers can mitigate potential quality issues.

Managing Production Consistency

Maintaining consistency in the production process is vital to ensuring uniform quality across all mesh panels. Manufacturers employ standardized operating procedures, conduct regular training sessions for operators, and implement quality control checkpoints at each stage of production. This consistency helps prevent variations and ensures that every mesh panel meets the established quality standards.

Detecting and Resolving Defects

Despite rigorous quality control measures, defects can occasionally occur. Manufacturers utilize comprehensive defect detection systems to identify and rectify any issues promptly. This may involve reworking or replacing defective panels, conducting root cause analysis to prevent future occurrences, and continuously improving production processes to minimize defects.

Continuous Improvement Practices

To enhance quality control further, manufacturers embrace continuous improvement practices. This involves soliciting feedback from customers, monitoring industry trends, investing in research and development, and implementing innovative production techniques. Continuous improvement fosters a culture of excellence, allowing manufacturers to stay at the forefront of quality and innovation in the metal architectural decorative mesh industry.

Conclusion

The production of metal architectural decorative mesh requires a robust quality control process to ensure the final product meets the highest standards. From selecting quality materials to performing rigorous testing and inspection, manufacturers strive to deliver a product that excels in both aesthetics and functionality. By prioritizing quality control, metal architectural decorative mesh continues to be a sought-after material, transforming architectural projects with its unique blend of artistry and practicality.

FAQs

1.Q:What is the lifespan of metal architectural decorative mesh?

A:The lifespan of metal architectural decorative mesh can vary depending on factors such as material selection, maintenance, and environmental conditions. However, with proper care, high-quality mesh can last for decades.

2.Q:Can metal architectural decorative mesh be customized?

A:Yes, metal architectural decorative mesh can be customized to suit specific design requirements. Manufacturers offer a range of options in terms of wire diameter, mesh aperture, patterns, and finishes to meet the unique needs of each project.

3.Q:Are there any sustainability aspects to consider in the production process?

A:Yes, sustainability is an important consideration in the production of metal architectural decorative mesh. Manufacturers often strive to minimize waste, recycle materials where possible, and implement environmentally friendly surface treatment processes.

4.Q:How can I find a reliable manufacturer for metal architectural decorative mesh?

A:When searching for a reliable manufacturer, consider their experience, reputation, portfolio of past projects, and adherence to quality control standards. Seeking recommendations and conducting thorough research can help you find a manufacturer that meets your specific requirements.

5.Q:Can metal architectural decorative mesh be used in outdoor applications?

A:Yes, metal architectural decorative mesh is commonly used in outdoor applications. It is designed to withstand various weather conditions and can provide functionalities such as sun shading, privacy, and security in outdoor settings.