Architectural mesh is a type of metal fabric that is commonly used in architectural applications, including facades, interiors, and landscaping.

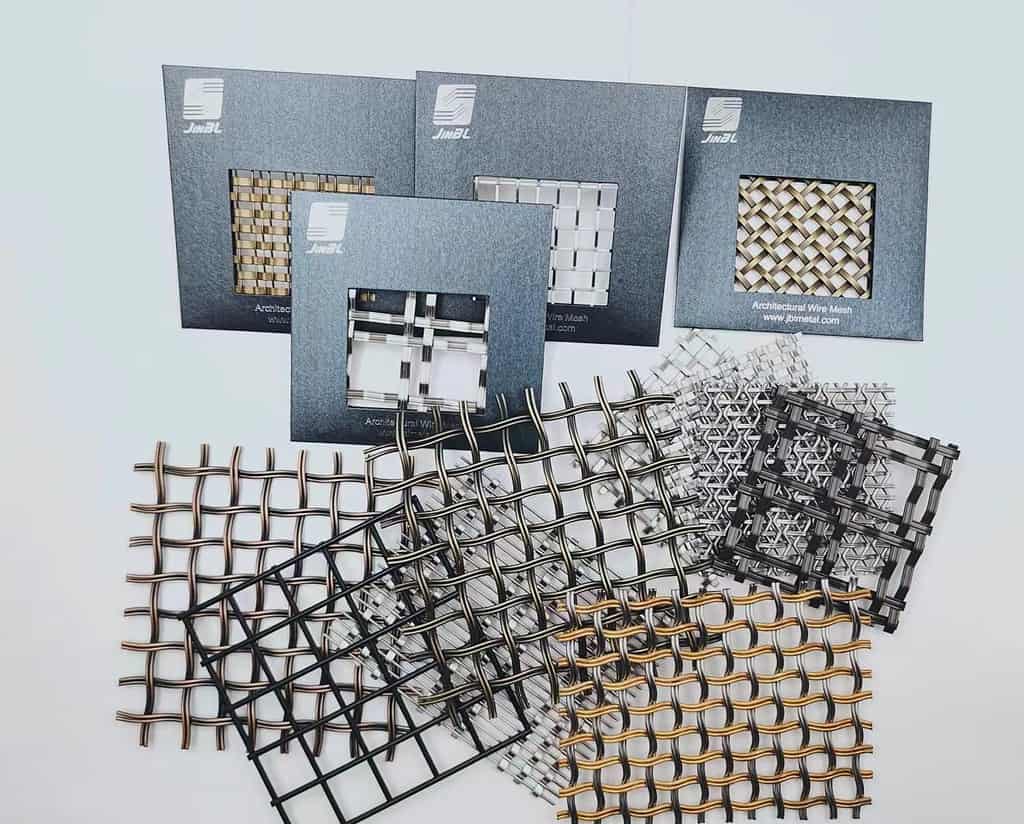

The material is made by weaving metal wires or cables together to create a mesh-like pattern.

The result is a flexible and durable material that can be used in a variety of ways to enhance the aesthetics and functionality of a building.

When it comes to facades, architectural mesh has become a popular choice among architects and designers due to its ability to provide several benefits. One of the main advantages of architectural mesh is its ability to improve ventilation and reduce energy costs.

By allowing air to flow freely through the mesh, the material can help regulate the temperature inside the building, reducing the need for heating and cooling systems.

Another advantage of architectural mesh is its ability to provide an aesthetically pleasing appearance. The material can be used to create a variety of patterns and designs, allowing architects and designers to create unique and visually appealing facades.

However, choosing the right architectural mesh for a facade application can be a challenging task, especially for those who are not familiar with the material. In the following sections, we will discuss the key factors that need to be considered when choosing architectural mesh for a facade application.

Material Selection:

The first factor that needs to be considered when choosing architectural mesh for a facade application is the material selection.

Architectural mesh is typically made from metal materials such as stainless steel, aluminum, and copper.

Each material has its own unique characteristics and properties that can impact its suitability for a particular application.

Stainless steel is a popular choice for architectural mesh due to its durability, corrosion resistance, and aesthetic appeal. Stainless steel meshes can be used in a variety of environments, including coastal areas, where salt and moisture can cause corrosion.

Aluminum mesh is another popular choice due to its lightweight and corrosion-resistant properties. Aluminum meshes are often used in applications where weight is a concern, such as high-rise buildings.

Copper mesh is less commonly used than stainless steel and aluminum, but it can provide a unique aesthetic appeal. Copper meshes can develop a natural patina over time, which can create a distinctive look.

Design Considerations:

The second factor that needs to be considered when choosing architectural mesh for a facade application is the design considerations. Architectural mesh can be used to create a variety of patterns and designs, allowing architects and designers to create unique and visually appealing facades.

When it comes to the design of the mesh, the size of the openings and the pattern of the weave are two key factors to consider.

The size of the openings can impact the level of ventilation and light transmission, while the pattern of the weave can impact the overall appearance of the facade.

In addition to the design of the mesh itself, the installation method and the support structure are also important design considerations.

The mesh can be attached to the building using a variety of methods, including tensioning systems, clamps, and frames. The support structure must be able to withstand the weight of the mesh and the wind loads that may be applied to it.

Installation Methods:

The third factor that needs to be considered when choosing architectural mesh for a facade application is the installation method. The installation method can impact the appearance and functionality.