Introduction

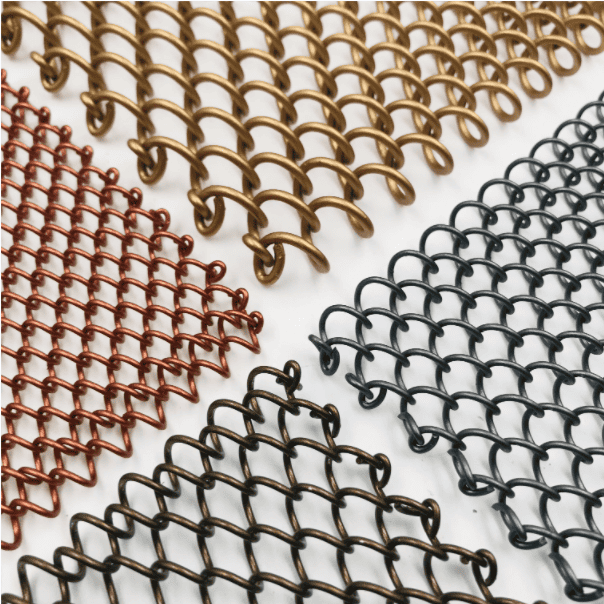

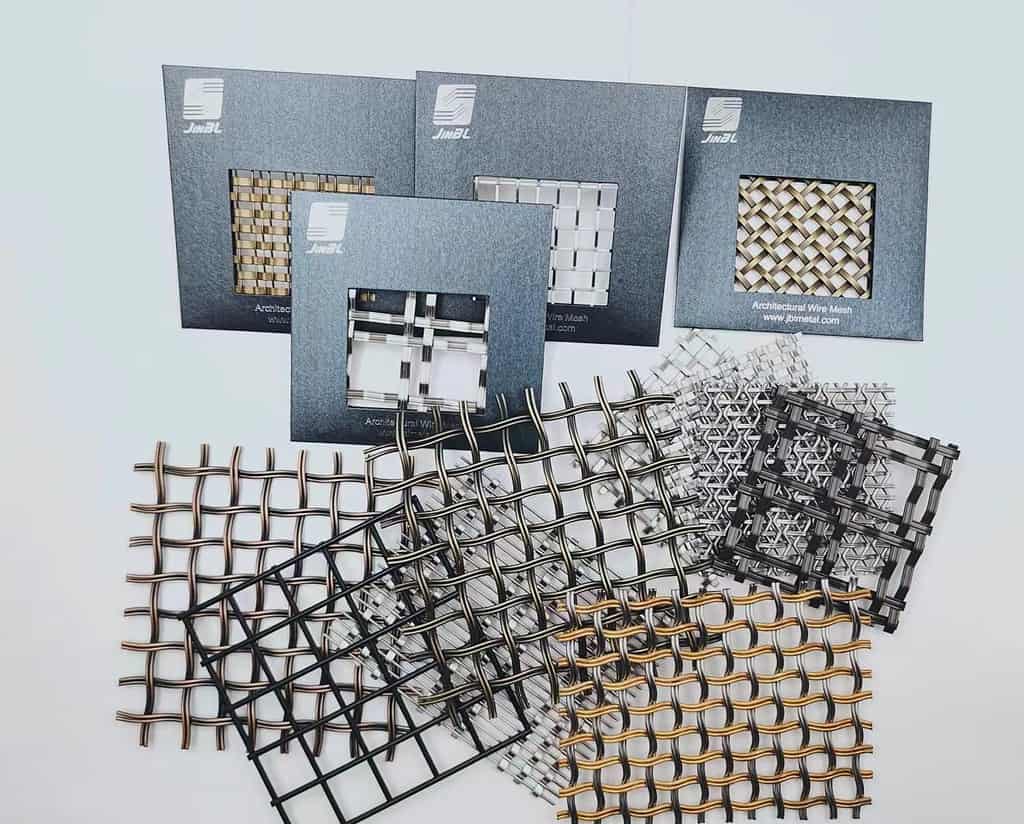

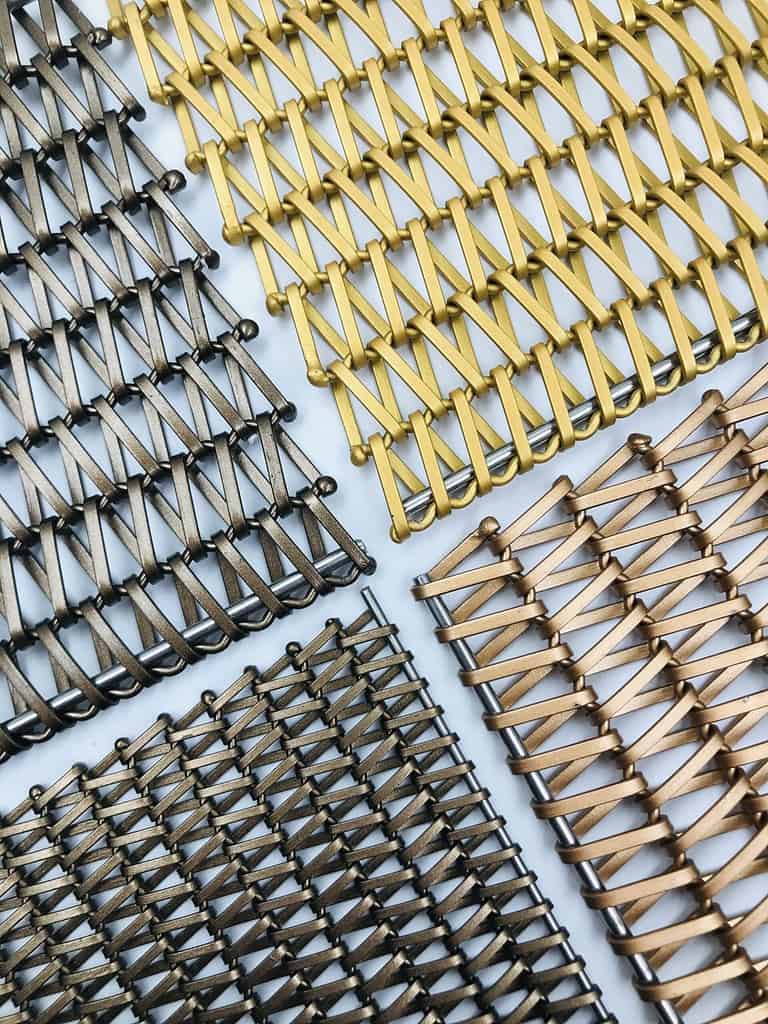

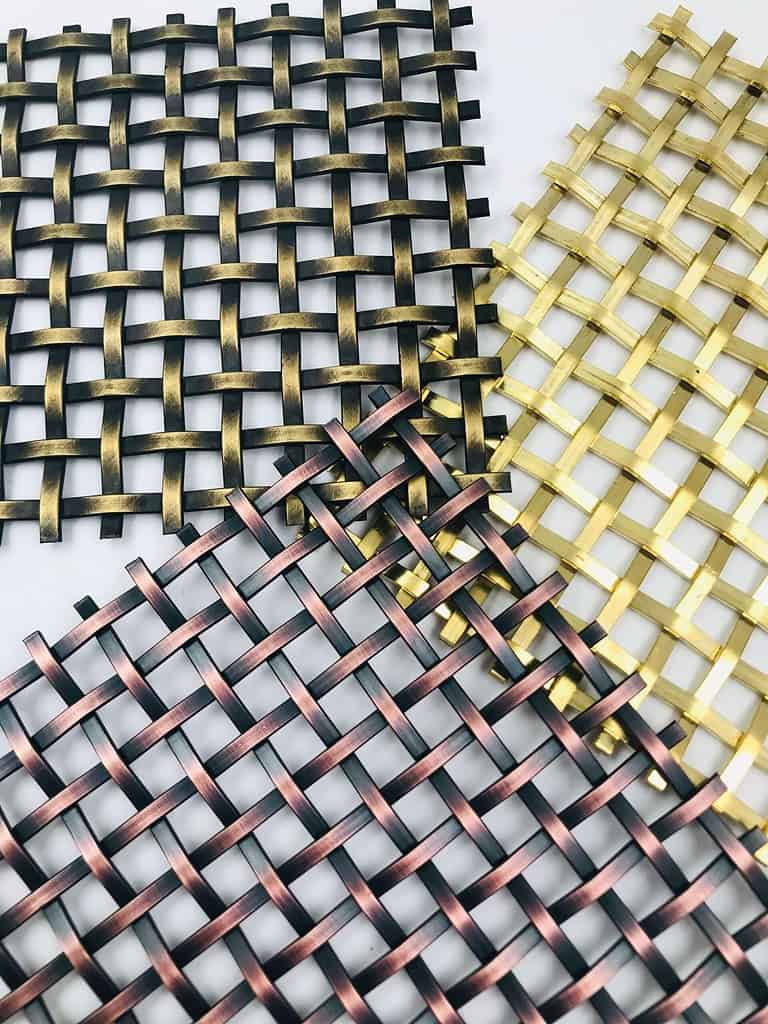

Metal decorative mesh is used in a variety of architectural and design applications, including facades, partitions, ceilings, and furniture. It is made of various metals such as stainless steel, aluminum, brass, and copper, and is available in various patterns, sizes, and finishes. However, the metal’s exposure to environmental factors such as moisture, sunlight, and air pollutants can cause corrosion, fading, and discoloration, affecting its aesthetic and functional properties.

To protect metal decorative mesh from these issues, it is essential to choose the right surface treatment. Surface treatments can enhance the metal’s durability, appearance, and resistance to corrosion, abrasion, and weathering. This article will provide an overview of the various surface treatments available for metal decorative mesh and their benefits.

Importance of Surface Treatments for Metal Decorative Mesh

Surface treatments play a vital role in maintaining the appearance and longevity of metal decorative mesh. They provide a protective coating that can prevent the metal from corroding or discoloring. Surface treatments can also enhance the metal’s aesthetic appeal and provide additional features such as scratch resistance or anti-graffiti properties.

Types of Surface Treatments

1. Galvanization

Galvanization is a process of applying a protective zinc coating to the metal decorative mesh. This treatment can be done through two methods: hot-dip galvanizing or electro-galvanizing. Hot-dip galvanizing involves dipping the mesh into a bath of molten zinc, while electro-galvanizing involves applying a zinc coating through an electric current.

Galvanization provides excellent corrosion resistance and can prevent rust and degradation. It is a cost-effective surface treatment and can provide a long-lasting protective layer to the metal decorative mesh.

2. Powder Coating

Powder coating involves applying a dry powder to the metal decorative mesh, which is then baked onto the surface. This treatment provides a durable, long-lasting finish that can resist scratches, chipping, and fading. Powder coating is available in a range of colors and textures, making it an excellent option for decorative mesh with specific design requirements.

3. Anodization

Anodization is a process of creating a protective oxide layer on the surface of the metal decorative mesh. This treatment involves immersing the mesh in an electrolytic solution and passing an electric current through it. This process forms an oxide layer on the surface, which can provide corrosion resistance, color stability, and scratch resistance.

Anodization is commonly used on aluminum decorative mesh and can provide an attractive, low-maintenance finish.

4. Painting

Painting is a surface treatment that involves applying a liquid coating to the metal decorative mesh. This treatment can provide a range of colors and finishes, including matte, gloss, or metallic. Painting can enhance the metal’s aesthetic appeal and provide additional features such as UV protection or anti-graffiti properties.

However, painting may not provide long-lasting protection against.

Factors to Consider When Choosing Surface Treatments

If you’re in the market for a metal decorative mesh, it’s important to consider the surface treatments that are available to you. These treatments can help protect your mesh from wear and tear, as well as enhance its appearance. But with so many options to choose from, how do you know which one is right for your needs? In this article, we’ll discuss the factors to consider when choosing surface treatments for your metal decorative mesh, as well as the benefits they provide.

Factors to Consider

- Material: The type of metal that your decorative mesh is made from will impact which surface treatments are appropriate. For example, stainless steel mesh may require different treatments than copper mesh.

- Environment: Where your mesh will be installed and the conditions it will be exposed to are also important factors to consider. If your mesh will be installed outdoors or in a high-moisture environment, you may need a more durable treatment.

- Aesthetics: If you’re looking to enhance the appearance of your mesh, you’ll want to consider surface treatments that provide a decorative finish, such as powder coating or electroplating.

- Budget: Different surface treatments come at different price points, so it’s important to consider your budget when choosing a treatment.

Common Surface Treatments for Metal Decorative Mesh

- Powder Coating: Powder coating involves applying a dry powder to the surface of the mesh, which is then heated to create a hard, durable finish. This treatment is popular for its versatility and range of color options.

- Electroplating: Electroplating involves applying a layer of metal to the surface of the mesh using an electric current. This treatment is popular for its ability to provide a decorative finish and improve corrosion resistance.

- Anodizing: Anodizing involves using an electric current to create a layer of oxide on the surface of the mesh, which improves its corrosion resistance and can provide a decorative finish.

- Galvanizing: Galvanizing involves coating the surface of the mesh with a layer of zinc, which provides excellent corrosion resistance.

- Painting: Painting the mesh can provide a decorative finish and protect it from the elements, but it may not be as durable as other treatments.

Benefits of Surface Treatments for Metal Decorative Mesh

- Corrosion Resistance: Surface treatments can help protect your mesh from corrosion, which can prolong its lifespan.

- Aesthetic Enhancement: Certain surface treatments can enhance the appearance of your mesh, making it more visually appealing.

- Wear Resistance: Surface treatments can help protect your mesh from wear and tear, which can be particularly important in high-traffic areas.

- Durability: Depending on the treatment you choose, your mesh can become more durable and long-lasting.

Conclusion

Choosing the right surface treatment for your metal decorative mesh is an important decision that will impact the look and durability of your mesh. Factors to consider include the material of your mesh, the environment it will be installed in, the aesthetics you’re looking for, and your budget. With the right surface treatment, your mesh can be both visually appealing and long-lasting.

FAQS

1.Can all metal decorative meshes be treated with surface treatments?

Not all metal decorative meshes are suitable for all surface treatments. The type of metal and the intended use of the mesh will impact which treatments are appropriate.

2.How long does a surface treatment last on metal decorative mesh?

The lifespan of a surface treatment will depend on the type of treatment and the conditions the mesh is exposed to. Some treatments may last for several years, while others may need to be reapplied more frequently.

3.Are surface treatments for metal decorative mesh expensive?

The cost of surface treatments can vary depending on the treatment and the size